Laser cutting sheet

In the laser cutting that is done on metals, the laser beam is focused with power and according to the design that is stored in the device’s memory, the cutting of metals is done in different dimensions. In metal cutting by laser, it is no longer necessary to do machining after cutting for cleaning, and all work requirements such as pleating and burning are done at the same time. Laser cutting can be done almost on most metals, metals such as steel, iron and aluminum are the most used in laser cutting of metals.

Using a laser to cut metals has advantages.

Laser cutting is very accurate and the work can be done with minimal damage.

It cuts a large number of parts uniformly and simultaneously in a short time.

Types of laser cutting:

Steel laser cutting

Galvanized laser cutting

Laser cutting of steel

Iron laser cutting

![]() Laser cutting of metals is one of the services of Humpa Saze Pars Company.

Laser cutting of metals is one of the services of Humpa Saze Pars Company.

Laser cutting sheet

In the laser cutting that is done on metals, the laser beam is focused with power and according to the design that is stored in the device’s memory, the cutting of metals is done in different dimensions. In metal cutting by laser, it is no longer necessary to do machining after cutting for cleaning, and all work requirements such as pleating and burning are done at the same time. Laser cutting can be done almost on most metals, metals such as steel, iron and aluminum are the most used in laser cutting of metals.

Using a laser to cut metals has advantages.

Laser cutting is very accurate and the work can be done with minimal damage.

It cuts a large number of parts uniformly and simultaneously in a short time.

Types of laser cutting:

Steel laser cutting

Galvanized laser cutting

Laser cutting of steel

Iron laser cutting

![]() Laser cutting of metals is one of the services of Humpa Saze Pars Company.

Laser cutting of metals is one of the services of Humpa Saze Pars Company.

Laser cutting of pipes and profiles

The use of pipes and profiles due to their light weight, along with maintaining their strength and economic efficiency, has caused an increasing demand for bending pipes and profiles in various industries. Pipes and profiles are the most widely used type of pipes in the installation systems of construction projects and petrochemical industries. , oil and gas, and automotive industries, which are produced in different types and sizes and are used in different purposes and applications. In the past, traditionally, manual or mechanical tools such as a saw or air gas were used to cut pipes and profiles; But today, with the progress in the field of lasers, laser cutting of pipes and profiles is done with much more precision and at a higher speed without additional pleats compared to other methods.

Advantages of laser cutting of pipes and profiles

In the laser cutting of pipes and profiles, there is no need to make templates and there is no design limitation, and all complex designs and two-dimensional maps can be easily cut.

Creating complex and flexible designs

High accuracy and speed

Quality cuts

Low waste

No change in metal structure during cutting

The devices used for cutting pipes and profiles have the ability to cut steel, iron, aluminum, copper and brass metals with high precision.

![]() Laser cutting of pipes and profiles is one of the services of Humpa Saze Pars Company. The highest quality and most advanced technologies for laser cutting of pipes and profiles in various industries are performed with controlled and enhanced laser radiation.

Laser cutting of pipes and profiles is one of the services of Humpa Saze Pars Company. The highest quality and most advanced technologies for laser cutting of pipes and profiles in various industries are performed with controlled and enhanced laser radiation.

Laser cutting of pipes and profiles

The use of pipes and profiles due to their light weight, along with maintaining their strength and economic efficiency, has caused an increasing demand for bending pipes and profiles in various industries. Pipes and profiles are the most widely used type of pipes in the installation systems of construction projects and petrochemical industries. , oil and gas, and automotive industries, which are produced in different types and sizes and are used in different purposes and applications. In the past, traditionally, manual or mechanical tools such as a saw or air gas were used to cut pipes and profiles; But today, with the progress in the field of lasers, laser cutting of pipes and profiles is done with much more precision and at a higher speed without additional pleats compared to other methods.

Advantages of laser cutting of pipes and profiles

In the laser cutting of pipes and profiles, there is no need to make templates and there is no design limitation, and all complex designs and two-dimensional maps can be easily cut.

Creating complex and flexible designs

High accuracy and speed

Quality cuts

Low waste

No change in metal structure during cutting

The devices used for cutting pipes and profiles have the ability to cut steel, iron, aluminum, copper and brass metals with high precision.

![]() Laser cutting of pipes and profiles is one of the services of Humpa Saze Pars Company. The highest quality and most advanced technologies for laser cutting of pipes and profiles in various industries are performed with controlled and enhanced laser radiation.

Laser cutting of pipes and profiles is one of the services of Humpa Saze Pars Company. The highest quality and most advanced technologies for laser cutting of pipes and profiles in various industries are performed with controlled and enhanced laser radiation.

sheet bending

Bending of metal sheets is one of the most widely used operations in the industry and is used for various purposes such as making metal boxes in the electronics industry, construction, livestock and agriculture, shipbuilding, factories, etc. One of the applications of this process is creating a curve in a sheet. Also, converting sheet into studs with different sections and in some cases circular shapes is very widely used.

Various devices are used to bend metal sheets. One of the common machines for this work is CNC press brake. For bending, the metal sheet is placed on a hollow part called Sembe and is kept fixed by applying the pressure of heavy plates. Humpa company with engineers and human resources have high skill, expertise and experience in sheet cutting and bending.

![]() Metal bending is one of the services of Humpa Saze Pars Company.

Metal bending is one of the services of Humpa Saze Pars Company.

sheet bending

Bending of metal sheets is one of the most widely used operations in the industry and is used for various purposes such as making metal boxes in the electronics industry, construction, livestock and agriculture, shipbuilding, factories, etc. One of the applications of this process is creating a curve in a sheet. Also, converting sheet into studs with different sections and in some cases circular shapes is very widely used.

Various devices are used to bend metal sheets. One of the common machines for this work is CNC press brake. For bending, the metal sheet is placed on a hollow part called Sembe and is kept fixed by applying the pressure of heavy plates. Humpa company with engineers and human resources have high skill, expertise and experience in sheet cutting and bending.

![]() Metal bending is one of the services of Humpa Saze Pars Company.

Metal bending is one of the services of Humpa Saze Pars Company.

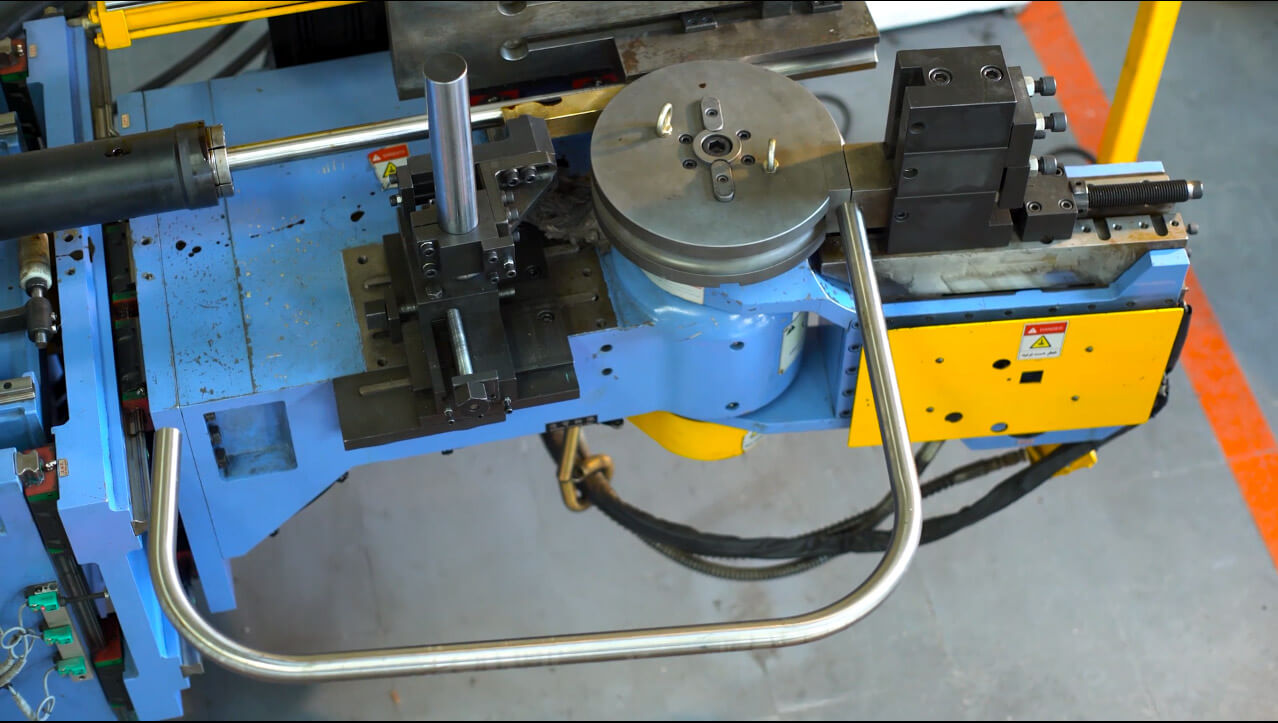

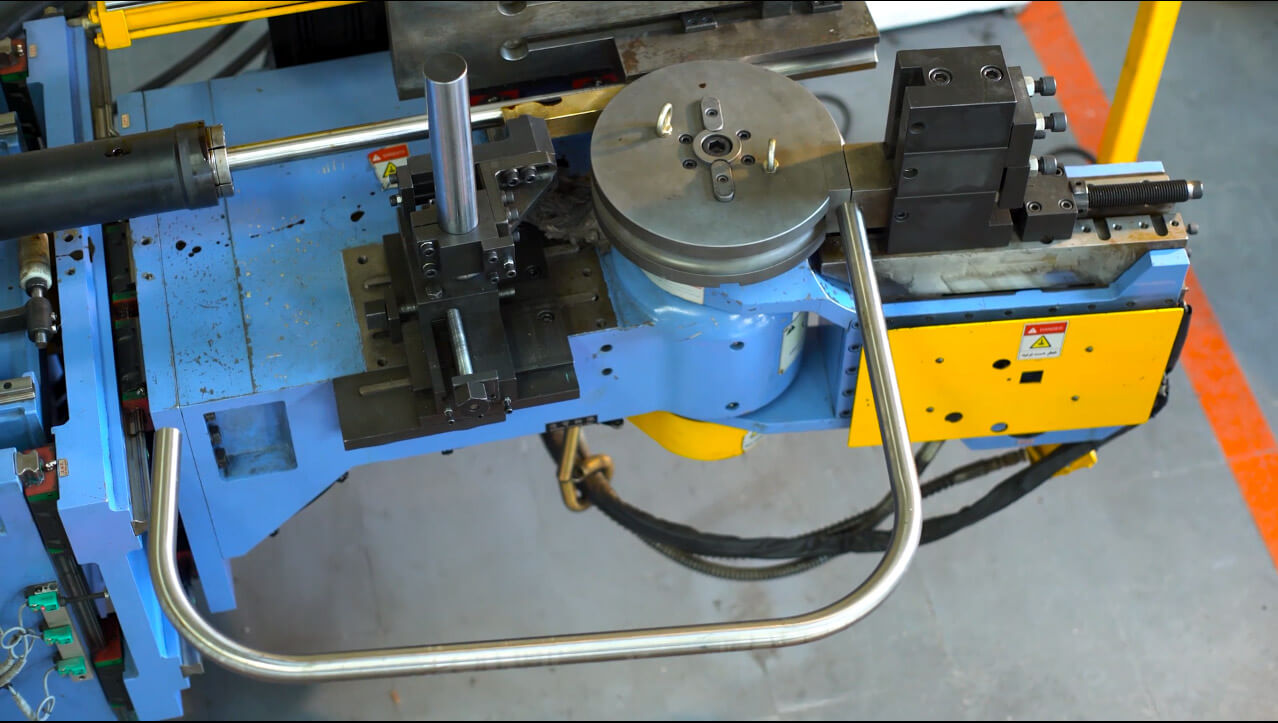

Pipe and profile bending

One of the most popular and widely used methods of cutting metals, especially iron, is the CNC method, and the reason for the popularity of this method is the absence of human intervention and the zero possibility of human error. We at Humpa company, using CNC tube and profile bending machine HC500Hanjie from Taiwan with the maximum power of bending iron pipe with an external radius of 50 mm and iron can 45×45 mm with a sheet thickness of 2.5 mm, we can bend all kinds of your orders. We will provide CNC tube and profile. The technology and intelligence of this device provides the best quality for your requested parts.

![]() Pipe and profile bending is one of the services of Humpa Saze Pars Company.

Pipe and profile bending is one of the services of Humpa Saze Pars Company.

Pipe and profile bending

One of the most popular and widely used methods of cutting metals, especially iron, is the CNC method, and the reason for the popularity of this method is the absence of human intervention and the zero possibility of human error. We at Humpa company, using CNC tube and profile bending machine HC500Hanjie from Taiwan with the maximum power of bending iron pipe with an external radius of 50 mm and iron can 45×45 mm with a sheet thickness of 2.5 mm, we can bend all kinds of your orders. We will provide CNC tube and profile. The technology and intelligence of this device provides the best quality for your requested parts.

![]() Pipe and profile bending is one of the services of Humpa Saze Pars Company.

Pipe and profile bending is one of the services of Humpa Saze Pars Company.

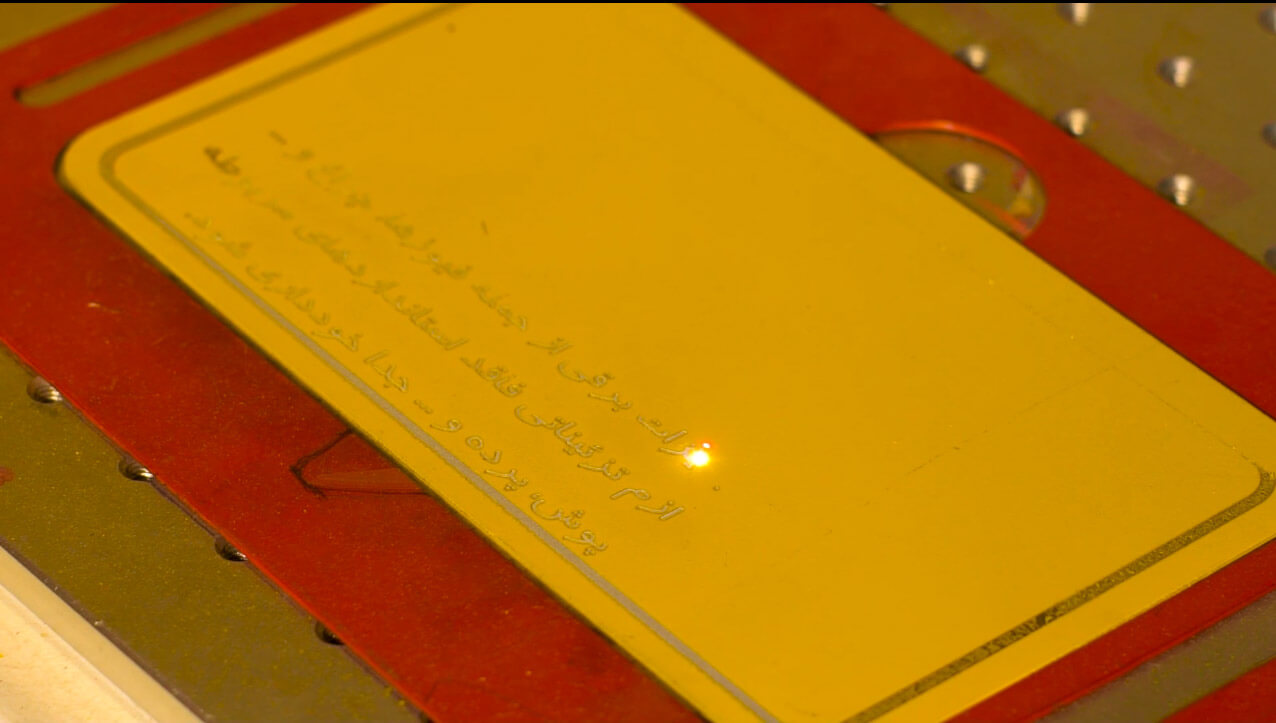

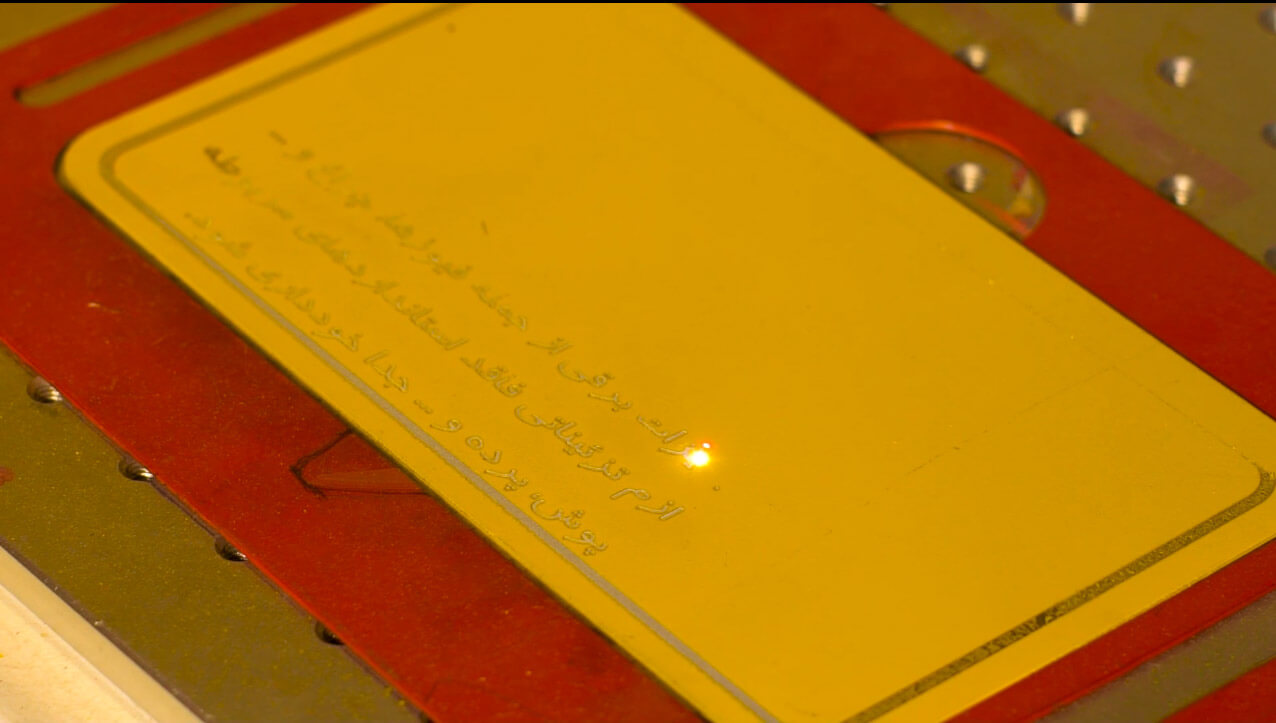

Laser engraving

It is a method that can be used to engrave objects and metals.

Natural materials such as stone, glass, metals

and industrial materials

Laser engraving of metals with a laser device is an excellent solution for inserting your logo on the product and as a result, more effective. With the use of metal laser devices, it is possible to perform laser engraving or marking on a wide range of materials. With these devices, it is possible to engrave with a very small depth (a few hundredths of a millimeter) on a part of metals and metal alloys, which are used in automotive industries, hospital equipment, catering services, gold industry, machine tools (drill, drill, razor). saw and…) is used.

Types of laser engraving:

Laser engraving in the automotive industry

Laser engraving of advertising products such as (badge, business card, flash memory, pen, power bank)

Laser engraving of digital goods such as (tablets, laptops and mobile phones)

Engraving special gifts

Laser engraving of medical and hospital equipment

Laser engraving of military parts

Serial laser engraving on instruments and measuring devices

Laser engraving of machine tools (drill, drill, saw blade)

Laser engraving of gold and jewelry

Laser engraving of rhinestones and ornaments

![]() Laser engraving is one of the services of Humpa Saze Pars company.

Laser engraving is one of the services of Humpa Saze Pars company.

Laser engraving

It is a method that can be used to engrave objects and metals.

Natural materials such as stone, glass, metals

and industrial materials

Laser engraving of metals with a laser device is an excellent solution for inserting your logo on the product and as a result, more effective. With the use of metal laser devices, it is possible to perform laser engraving or marking on a wide range of materials. With these devices, it is possible to engrave with a very small depth (a few hundredths of a millimeter) on a part of metals and metal alloys, which are used in automotive industries, hospital equipment, catering services, gold industry, machine tools (drill, drill, razor). saw and…) is used.

Types of laser engraving:

Laser engraving in the automotive industry

Laser engraving of advertising products such as (badge, business card, flash memory, pen, power bank)

Laser engraving of digital goods such as (tablets, laptops and mobile phones)

Engraving special gifts

Laser engraving of medical and hospital equipment

Laser engraving of military parts

Serial laser engraving on instruments and measuring devices

Laser engraving of machine tools (drill, drill, saw blade)

Laser engraving of gold and jewelry

Laser engraving of rhinestones and ornaments

![]() Laser engraving is one of the services of Humpa Saze Pars company.

Laser engraving is one of the services of Humpa Saze Pars company.

Electrostatic painting

El-Rang electrostatic painting is an industrial color and is widely used in the field of painting all kinds of metal surfaces. Electrostatic Electrostatic powder paints are the best type of industrial paint that have the least harmful effects on the environment and do not threaten the health of workers.

![]() Electrostatic painting is one of the services of Humpa Saze Pars Company.

Electrostatic painting is one of the services of Humpa Saze Pars Company.

Electrostatic painting

El-Rang electrostatic painting is an industrial color and is widely used in the field of painting all kinds of metal surfaces. Electrostatic Electrostatic powder paints are the best type of industrial paint that have the least harmful effects on the environment and do not threaten the health of workers.

![]() Electrostatic painting is one of the services of Humpa Saze Pars Company.

Electrostatic painting is one of the services of Humpa Saze Pars Company.